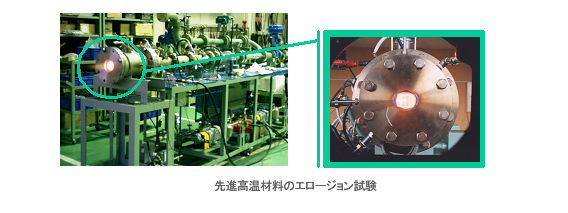

What's High Temperature Environmental Test Rig

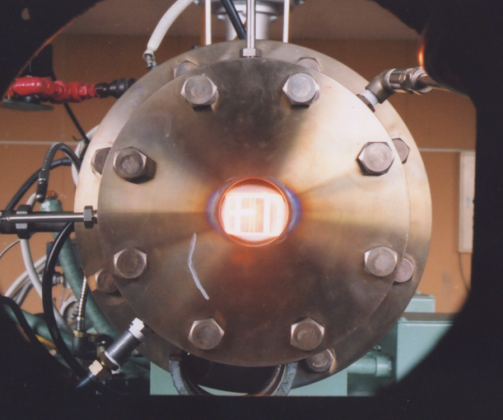

These days, especially for improvement of efficiency and emission in gas turbine industry for both aerospace and power gen, ceramic materials and advanced composite materials are being employed in ever increasing variety of applications, frequently supplanting traditional engineering materials, due to their light weight, low friction and superior resistance to heat and corrosion. At the early stage of product development, however, it is prudent to perform appropriate testing to prove the suitability and reliability of the ceramic materials and advanced composite materials before incorporating it into the new product.The combustion chamber generates extreme hard conditions, which is capable of achieving to beyond 1,600deg C of outlet temperature and 500m/s of flow velocity, due to performing a requisite testing economically rather than testing with actual engine.

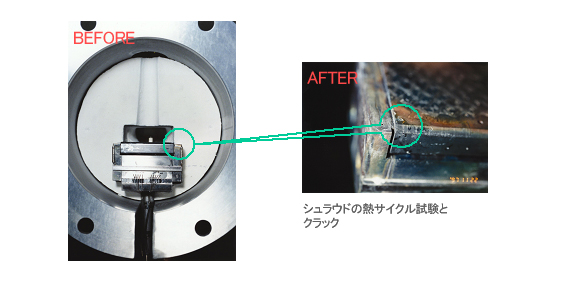

In many applications, the ability of the boundary layers of thermal barrier coating to withstand the repeated thermal cycle/shock is of particular importance.

<Test examples>

Thermal Cycle Fatigue Testing

Thermal Shock Testing

Erosion Testing

Corrosion Testing

Past Production Examples

Integration of Tensile Test Rig

Both thermal and tensile stresses can be loaded to the test pieces, due to more practical verification.